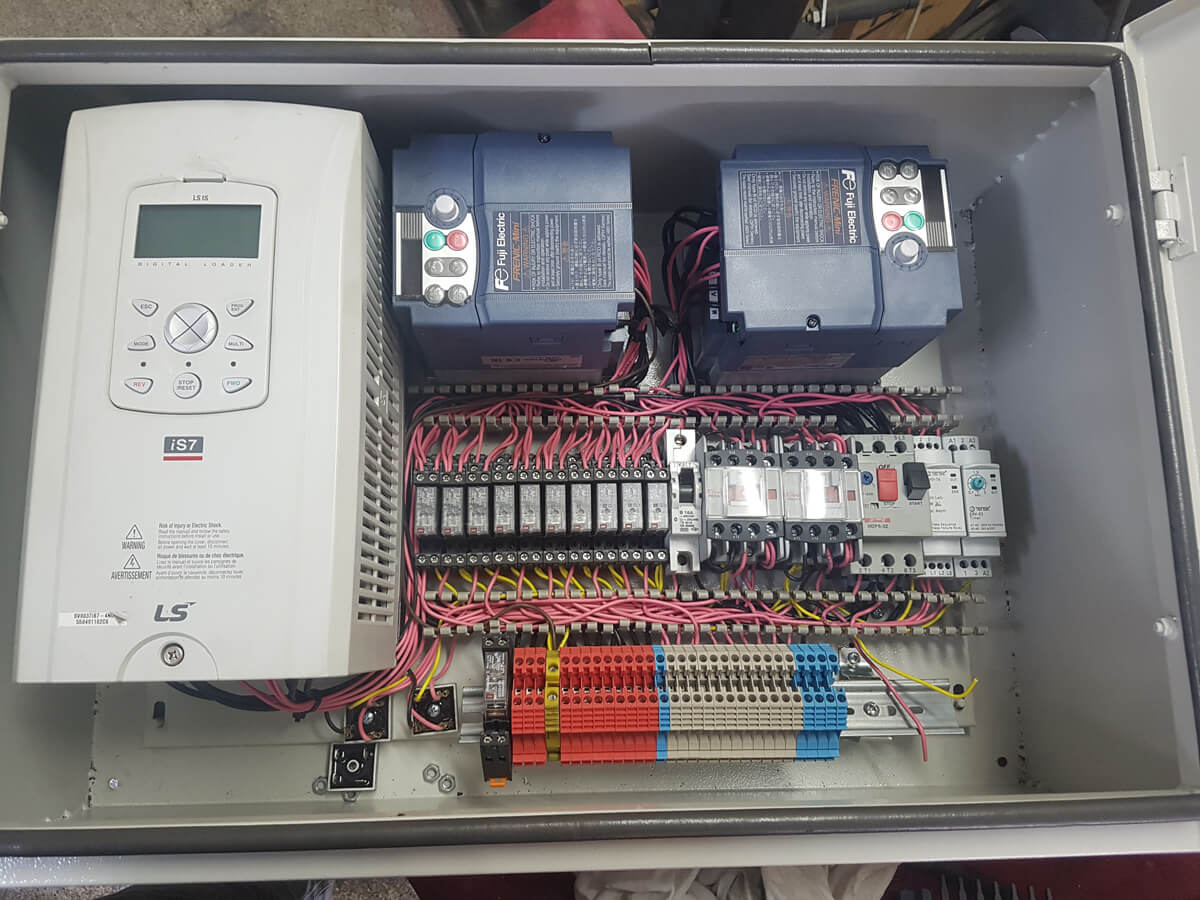

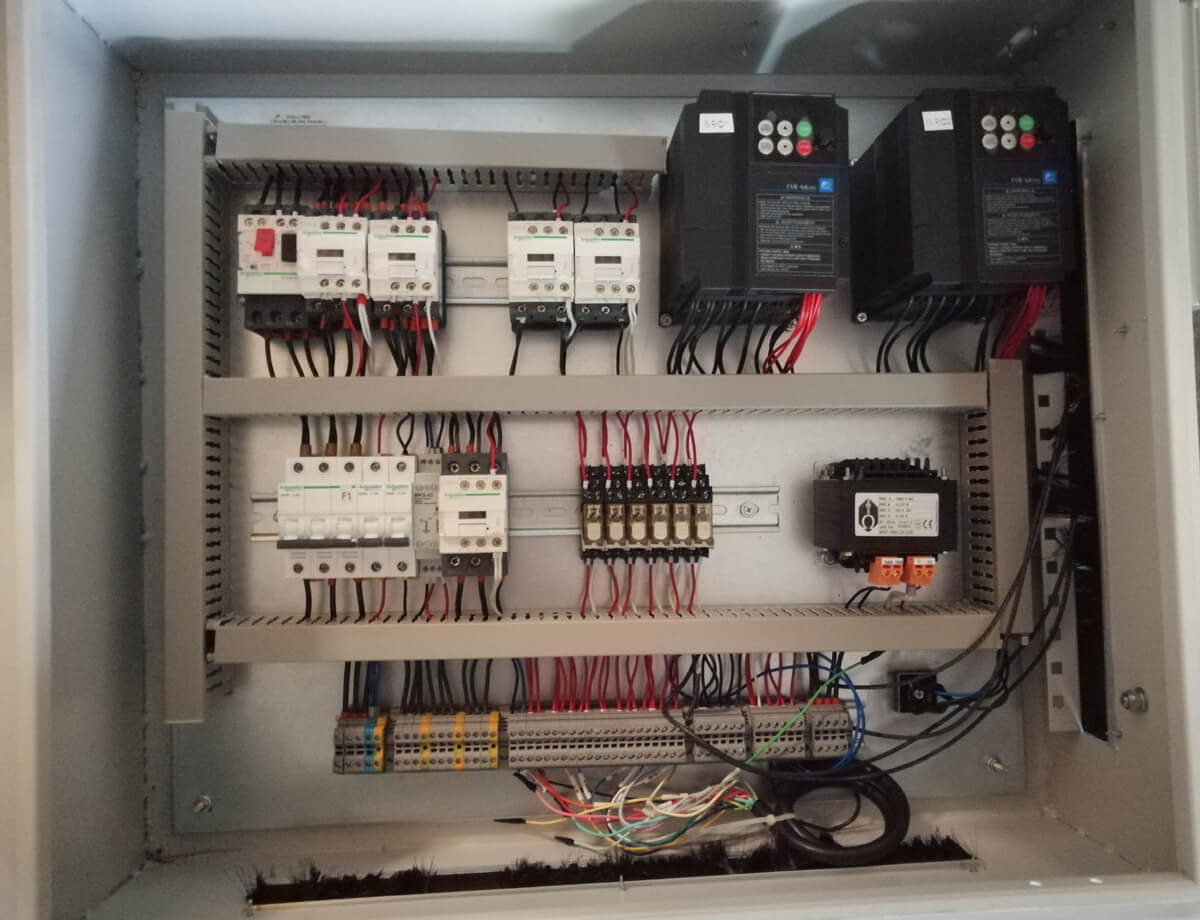

In any commercial or residential building, these panels are always included or can be included. These panels are known as automation panels, which are formed together with the main cable. These panels are integrated with the main electrical cable and are typically composed of reliable components that optimize device performance by facilitating the distribution of electricity. Circuit breakers regulate the flow of electricity and ensure proper distribution throughout the building.

PLC panels are also available, which aid in the correct distribution of power and can resolve any issues that arise. These panels ensure optimal performance at all times. Crane panels are among the most commonly used panels in terms of performance criteria. They distribute electricity according to the needs of the individual building, ensuring proper distribution throughout the system.

What is the Function of an Automation Panel?

The panels located in this system are responsible for maintaining proper energy distribution and facilitating various operations. They feature connection points, which are integrated with components such as Earth Leakage to prevent electrical shocks or fires. Typically, they are referred to as single-speed panels. They are formed with panels that include the main distribution line, which is frequently discussed in workshops and factories. Depending on the building type, low voltage outputs of transformers are arranged and energy distribution is provided by coming to the main distribution panel.

Thus, the energy flows into the measurement panel, and then the main distribution panel, where it is outputted through a switch and enters the energy distribution panel on the main floor. The double-speed panel ensures that voltage outputs or inputs are completed automatically, allowing for easy assembly when required. The power requirements of the system are subject to change based on the size of the facility, with larger facilities requiring larger panels or dimensions to accommodate the increased power demands.

What Are the Features of an Automation Panel?

Automation panels consist of approximately 3 bands. They are located in a size that does not exceed 2 millimeters in thickness with the main distribution panels. When designing these, experts in the field are always consulted. It is important that they are designed according to certain standard dimensions and comply with these standards. After the dimensions and standards are determined, the panels are manufactured accordingly. The pricing of the main panel systems, which are mostly used, is determined by the dimensions.

The panel types that are mostly used are those with electrical meters. As many new methods are developed today, the pricing of these main panels constantly changes. In general, the price of an automation panel increases in proportion to a certain budget. In recent years, it is also widely used in transformer facilities. Its installation location is known as the side of the outside pole.

What Materials are Used for Automation Panels?

Automation panels are typically composed of various materials such as current transformers, switches, busbars, outlets, and lamps, which are categorized based on their specific functions. For example, rectangular copper busbars are used to fix outputs in switches in main distribution panels located in power plants, where very large and user-friendly switches are employed.

Different names are assigned to switches for small and large currents, and they are responsible for controlling the input movements of receivers or open-close functions in the main distribution panels. In terms of their types and characteristics, they are typically categorized into three distinct groups.

What Should be Included in Automation Panels?

In order to meet the necessary requirements, a system has been developed that involves planning and decision-making based on specific criteria. Once the plans have been finalized, the assembly process can begin. It is important to ensure that the panels are installed at least 10 centimeters above ground level and that the fixators are positioned correctly based on pre-determined drawings. By following these guidelines, the operation of the system can be carried out without any problems.

It is also essential to connect and clean the fuses automatically and to install all materials according to the required standards. Different brands must be selected for each switch, as each switch requires different materials. By doing so, the standard criteria are automatically met. The panels must contain plates that can provide insulation functions and can be united with movable covers to protect the panels from external influences.

What Are the Technical Features of Automation Panels?

The moving covers are insulated using a multi-stranded braided insulation that is around 16 square millimeters. Yellow or green isolated conductors are used for grounding. It is important to make sure that the connections are properly connected to the body or cover on both ends. Another important aspect is that the panel is made entirely of metal coating and needs to be cleaned with steel accents.

Typically, a matte paint is used for the coating, and an aluminum plate is placed on the black color and labeled accordingly. The process can be carried out from either the top or the bottom. All suitable places and projects for the panel should be specified and labeled with table numbers. The distribution of electricity is done automatically, and this system is known for its strong power supply.

How are Automation Panel Categories Classified?

Like all products, these products are also divided into main categories. Versions with single or double doors are available. In addition, configurations that can be 4-way or 8-way are also available in the current structure. Generally, two-door automation panel varieties are consumed more in small facilities.

Double-door distributions are made for people in heavy or more applications. As these facilities are suitable for commercial use, panels are designed accordingly. After all types of panels to be used are designed, appropriate safety measures are taken. It is known that these panels have many branches and statuses in their own fields.

How are Automation Panel Prices Determined?

The prices of distribution panels can fluctuate frequently for both residential and commercial use. It is crucial for individuals to choose the most appropriate panel for their specific needs. Therefore, it is difficult to provide an exact cost for these panels. High-quality panels tend to have higher prices. Using them with an electric system provides benefits to users and increases the price criterion.

The amount of content or information of automation panels can create variability in price. As there are panels that need to be covered with the principles of keeping the heat at a constant level due to the safety concerns, attention should be paid to these issues.

How Often Should Automation Panels Be Maintained?

The maintenance of these panels should be checked every two months to ensure that there is no electrical leakage due to any context, and individuals who will use them should definitely apply to technical services. The more they are used and preferred, the more security measures should be taken. Their general maintenance should be done continuously and should not be neglected.

If you have any questions about the entire process, you can reach us via the information on our contact page.