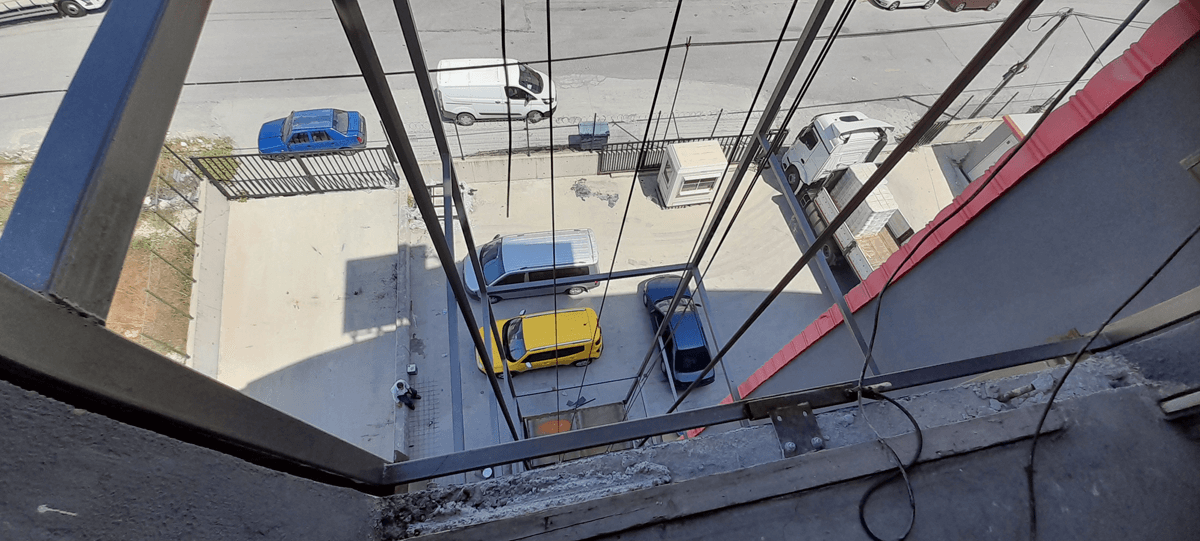

These are a type of elevator that facilitates the lifting and lowering of loads in various fields across the country. Freight elevators offer many advantages in our daily lives and can be used easily in both production and storage processes. They provide cost-effective solutions and ensure efficient results. The sector of rope freight elevators is progressing with technological advancements.

These elevators are placed advantageously by preferred companies and come in various forms and features. As they do not exist in a single form, they can be easily used in various production areas. They are budget-friendly and can be used in various production areas. They are commonly used as indoor freight elevators in buildings to transport goods or certain items. These elevators are durable and made from various materials.

They meet standards for easy and fast transportation and enable workers to complete their job faster and more efficiently. Freight elevators have no product restrictions and can transport a wide range of items. Thanks to the newly emerging exterior freight elevator, developments are increasing gradually. Everything is transported in a practical way.

What are the Features of a Freight Elevator?

These lifts are used worldwide and are now designed for ergonomic efficiency. They have a wide range of capacities, they can carry many heavy materials from 500 kilograms to 10,000 kilograms. Since they go through a meticulous manufacturing process, it is known that vehicles and products are not damaged, which is a sensitive issue. Fright elevators can be customized to fit specific height, depth, door width, door length, and load requirements.

There are two ways to achieve the desired transportation target, which can be done through electric or hydraulic lifts. Compared to standard elevators, freight elevators have a high degree of durability. This is known as one of their most distinctive and important features. They are also designed for seasonal conditions and can have single or double doors. The manufacturing processes are created within a certain period of time.

Freight elevators are classified based on the mass volumes they can carry and are equipped with button systems for entry. Special designs are emphasized in this sector, with safety being a top priority. High levels of safety measures are implemented, including various locking systems that can be activated in emergency situations.

What are the Types of Freight Elevators?

Freight elevators can be classified into two types: column and scissor. Column type elevators work with a column system and are the most basic method used widely in many fields, especially in factories. They are preferred in two or four column shapes because they are produced in different structures.

They can carry up to approximately 10,000 kilograms and are known as one of the most advanced models. Column type elevators are considered one of the most advanced models as they can produce significant results and reduce the workload in factories. Scissor type freight elevators, on the other hand, operate using a spring system and are designed with a bidirectional scissor system to prevent collisions. The length of the scissor type elevator can be increased while the weight capacity varies constantly.

In which Areas are Freight Elevators Used?

Freight elevators are not limited to a specific sector and can be utilized in any location where a freight platform is available, such as schools, buildings, companies, and residences. They are highly preferred due to their ability to transport goods, which saves time and provides an advantageous process, especially in warehouses. Freight elevator prices varies depending on their weight capacity.

In various factory sectors, freight elevators are used in different locations for the transportation of materials. They can be used multiple times and are subject to maintenance and periodical checks to ensure their continued functionality. The elevators facilitate transportation from one point to another and are essential in providing active transportation services.

What are the Advantages of Freight Elevators?

The system offers various benefits, one of which is the easy transportation of goods. With the use of elevators, workers can relieve themselves of heavy loads and breathe easily, while people can transport goods without exerting themselves. The system is also considered safe and contributes to lighter workloads.

What are the Prices of Freight Elevators?

Prices for these systems vary depending on their types. High-quality materials and production methods can result in higher prices. Additionally, larger sizes and dimensions can also lead to increased costs. These systems have varying potential heights and widths, and larger options are often preferred. Ultimately, the size of the system is determined by the intended use and available space.

What Should Be Known About Freight Elevators?

Since these elevators are produced in certain standard sizes, they are provided quite fast and comfortably. They have been increasingly used in shopping centers and the construction industry. They are widely used in different fields and have improved over time. They also have a fast working principle because it provides quite a lot of savings. They operate quickly and save a lot of time.

The elevators are well-maintained and serviced regularly. They can be adjusted to meet specific requirements and can be operated either automatically or semi-automatically. In case of emergency, users can communicate with others using the elevator’s phone button. The floors are made of non-slip materials.

How Are Maintenance Works of Freight Elevators Carried Out?

The duration of an elevator’s lifespan is not fixed and is influenced by its usage patterns. The frequency and duration of maintenance intervals are linked to factors such as weight and transport conditions. Typically, elevators require regular maintenance checks every year, and in the event of any malfunction, maintenance personnel should be contacted immediately. Elevators play a significant role, which highlights their importance.

A correlation has been observed between the frequency of maintenance and the lifespan of elevators regarding their usage. The general public is aware that routine maintenance checks are conducted monthly to inspect elevator cabins or blocks.

How Does a Freight Elevator Work?

The elevators in this system operate using a push-button system that activates when loads are placed inside. The propeller mechanism then gradually pulls the elevator upwards, raising the level at which the load is carried. Elevators operating in this manner are generally considered safe for people and do not pose any safety concerns.

If you wish to contact us for all processes, you can reach us from the contact page information.